Effective Sorting Solutions More Important than Ever

Enya Zhang, who is in charge of Overseas Marketing at SNBC, explores the impact of Covid-19 on the industry and the demand for more automation.

“The global demand for online shopping since the start of the 21st Century has led to the rapid development of logistics automation technology. At the start of 2020, COVID-19 caused worldwide panic and people tried to reduce person-to-person contact to attempt to curb the pandemic. With contactless shopping being the new normal, online shopping has become the preferred way of purchasing pretty much everything from food, clothes, electronics to gifts and books. The COVID- driven boom of online shopping presented the logistics industry with a massive opportunity as well as the inherent challenges of meeting demand. Automatic sorting equipment is playing a significant role in the process of parcel delivery as it can improve sorting efficiency and reduce labour costs.

SNBC has been committed to the logistics industry for a long time. Several SNBC solutions have been provided to the express company and excellent results have been achieved. SNBC provides a complete set of solutions rather than just machines to express companies and these solutions have gained great popularity and recognition among customers. This year more express companies have chosen SNBC logistics automation equipment to relieve the pressure on sorting and delivery.

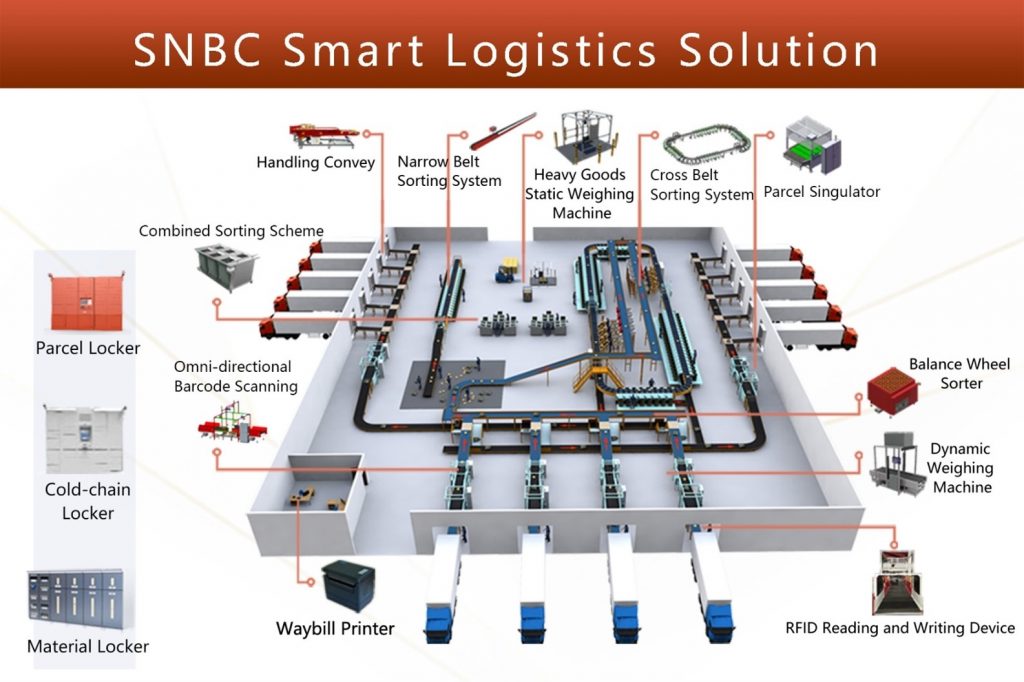

SNBC logistics industry solutions cover the whole process of package generation, sorting and delivery. In the parcel order generation phase, SNBC can provide solutions for label printing including the portable label printer used by couriers when collecting parcels, the desktop label printer used by e-commerce owners/express outlets when printing a waybill and the industrial barcode label printer used by sorting center/warehouse for various printing purposes.

In the parcel sorting phase, SNBC can provide the sorting center with one-stop automated solutions covering parcel unloading, sorting and loading, which can save more than 70% of the manpower of the sorting centre.

At present, the express sorting centre has two key functions: large parcel sorting and small parcel sorting. In traditional large parcel sorting, each conveyor requires manual work for parcel dragging, code scanning and parcel sorting while SNBC’s automated large parcel sorting solution can save the manpower spent on manual sorting. After entering the sorting area, parcels will be dragged apart one by one through the parcel singulator and the siding machine, and then pass the omni-directional barcode scanning machine which can scan the parcel barcode to get its weight and volume information. The RFID label of the large parcel will be read by the RFID tunnel machine before the parcel enters the sorting area. By analysing parcel information collected by the omni-directional barcode scanning machine and the RFID tunnel machine, the system can determine where the parcel should go next and then move the parcel to the right location, the swing wheel sorter distributes parcels to the specified direction.

With the traditional method of sorting small parcels, “manual work + conveyor mode” or “manual work + basket mode” relies on human memory to sort parcels and leads to low sorting efficiency and high error rate (8%). Besides, a large number of temporary workers are needed during peak periods, but it is difficult for temporary workers to remember routing information in a short time. SNBC’s automated small parcel sorting solution can lower the sorting error rate to one ten-thousandth. The product solutions mainly include two types: cross belt and straight line sorting systems. The cross belt is suitable for application scenarios with a large amount of sorting, high efficiency requirement and multi sorting directions. The straight line sorting system is suitable for application scenarios with a small area, no more than 100 sorting directions and an efficiency of less than 8000 pieces/hour. At present these two solutions have been applied by China post, JD logistics and other customers on a large scale.

This year SNBC has won lots of business to install logistics automation in China such as the parcel singulator for SF Express. In order to promote the development of logistics industry, SNBC will constantly update its products to meet the latest industry standard.