Reducing the cost and increasing the business value of new postal sorting facilities

The Design Process

Postal operators are continuously looking at ways to reduce operating cost to maintain competitiveness. One of the main ways to achieve this is to consolidate facilities into larger units where complex automated processing islands have been implemented. This level of complexity concerns the industry – and so it should. Many facility projects are characterised by: significant delayed commissioning; cost increases; and throughput and productivity expectations that are not met.

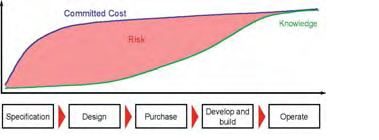

It is a worrying trend, and even the use of best practice methods and simulation/design tools by very experienced suppliers have not been able to prevent this. What goes wrong and how can it be done differently? It is our experience from not only the postal industry but across other industries that the most common cause of the problem is not getting the requirements right before the facility is commissioned. Insufficient knowledge about the design phase, where the big decisions are made, makes it impossible to predict problems down the line. Figure 1 illustrates the typical life cycle of a facility design process and the risk associated with each stage of the process.

The shaded area marked “Risk” illustrates that the highest level of risk is undertaken at the specification stage. The key to the project’s success is to align the specifications with the business objectives through a robust modeling process. However, the original solution often fails to deliver the business objectives due to a poor understanding of the business objectives.

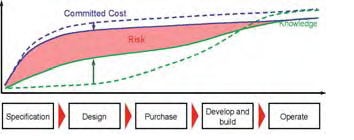

Figure 2 illustrates how the introduction of modeling techniques improves the depth and quality of knowledge in the crucial early design phases, when the requirements are defined and costs are committed. This approach enables postal organisations to recognize and address complications imposed by the business objectives and requirements upfront, substantially increasing theproject’s success rate.

Accurately determining requirements through a simulation aided design process

The Norwegian Post had completed a national network planning study, that addressed the processing roles, interfaces and service level agreements (SLA) each facility had to meet in order to fulfill its role in the national postal network. The national network strategy also imposed time horizons, technology selection, transportation, and other constraints such as the applied mail sorting strategy. One outcome of the national network study was the development of an automation strategy that would consolidate several smaller sorting centres into a new state of the art facility. In order to recommend a solution, finalise the business case, and prepare tendering material they needed to translate the business objectives into facility requirements specification. This specification should list the physical requirements (floor space, docks, layout etc.) as well as operational requirements (equipment configuration, automated internal transport etc.). Before the specification could be created it was key to fully understand how alternative solutions would meet the objectives. Simulation was used throughout the specification and design phases to explore alternatives and create requirements meeting the business needs. The applied facility simulation modeling integrated physical layout, sorting processes, business/operation rules and service levels agreements for mail exchange between affected facilities. The simulation aided design process made a significant impact in a number of areas, One specific example is outlined below.

Case Study: Detailed equipment and capacity requirements

The new mail centre had to accommodate a new process to automate letter carrier sequencing into delivery order. Initially, sorting capacities of the different process areas were determined using traditional spreadsheet calculations based on the anticipated work schedule and workload. The first objective of the simulation was to validate the feasibility of the operation’s approach and the anticipated work schedule. Simulations showed that the work schedule could not cope with a peak day. Outward sorting of First class mail was completed too late to meet departing transportation at 21:00. Instead of adding more capacity, the operational approach was challenged by the time shifting sequencing of the Second class mail operation to free up the necessary capacity. Simulation showed that this operation could be moved into a time window with unutilised capacity from 21:00 until 00:15 where the transports from the other outward sorting facilities (OOF) arrived.

The nature of the sequencing sort programmes prevented optimal usage of this unutilised capacity. The simulations highlighted the need for more equipment if this sort of strategy was to succeed. Buying in further equipment was going to be very costly so alternative solutions were devised and simulated. A new sequencing strategy was developed that combined the sequencing of First and Second class mail. This required an equipment upgrade, but because the machines were still on the drawing board this was a relatively inexpensive change. Had the equipment already been commissioned, the upgrade would have been impossible or very costly.

The new sequencing strategy significantly improved equipment utilisation. Two other benefits were also realised. Firstly, the investment in supporting machines for sequencing was reduced by 60%. Secondly, the management of the mail processing was simplified and the peak loads of the supporting systems were reduced to such a degree that a significant less costly solution for internal mail transport and consolidation became feasible.

Why was the capacity requirements calculated using spreadsheets not sufficient? Primarily because it did not facilitate building understanding as illustrated above and secondly it was too high level to prevent “black holes”. The significant effect of inaccessible capacity was not included in the spreadsheet calculations. Thus the benefits of the simulation analysis were to provide additional insights, which helped modify the requirement to create a solution that would eliminate problems identified. Another complicating factor was that distribution out of the facility was organized in time-waves, where the critical completion time limited the volume each sequencing program could process within the available timeframe.

Summary

Simulations force a consistent end to end view eliminating serious black holes. Modeling techniques will improve the depth and quality of knowledge in the early phases where the requirements are agreed and cost committed. In this phase, it is key that simulation skills are combined with strong industry knowledge to facilitate beneficial usage of the findings.

The benefits of this approach are significant – just imagine the cost of delaying the project by one year, the cost of re-building, and probably never being capable of reaching 100% of the original performance goals – as consultants, we see examples with t his scary outcome.

A full version of this article is available from the authors [email protected]. and

Figure 2: Introducing modeling techniquesearly in the facility design process willreduce the risk profile

Figure 1: A typical facility design process