Delivering a greener future

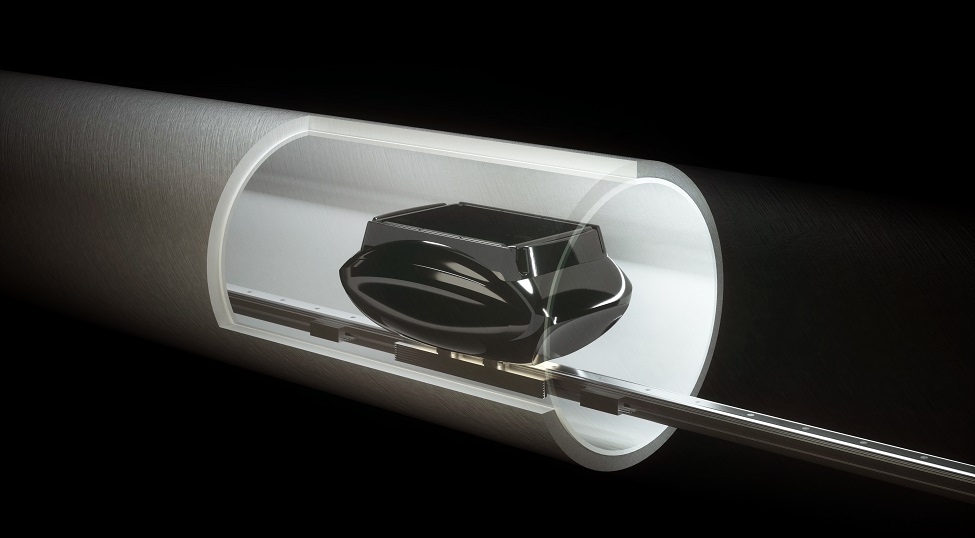

Inspired by hyperloop and armed with engineering expertise and a vision of cities with cleaner skies; Magway uses linear motors to propel parcels in sealed pipes along underground and overground tracks and reduces the need for heavy delivery vehicles on the road.

Inspired by hyperloop and armed with engineering expertise and a vision of cities with cleaner skies; Magway uses linear motors to propel parcels in sealed pipes along underground and overground tracks and reduces the need for heavy delivery vehicles on the road.

Ahead of Magway’s presentation at Post&Parcel Live, we spoke to Rupert Cruise, linear motor specialist and Co-Founder of Magway, to find out more about the ground-breaking north London-based company which aims to get e-commerce goods closer to the consumer in a more environmentally friendly way.

How did you get into engineering?

My grandfathers, father and uncles are mathematicians, physicists and engineers, so I have always grown up with a fascination for science and technology. I built my first levitating high-temperature superconductor at the age of 13 after reading about the discovery of new superconducting materials in Time Magazine. It was great fun to see the superconductor levitate when cooled with liquid nitrogen, however, the next step was to try and make it move. This was when I first discovered linear motors. I never really understood how linear motors worked and this led me to study electrical engineering.

How has your career developed?

Today I have been working with linear motors for over 30 years both as a researcher in academia and in deep level gold mines in South Africa. Following an MBA at Oxford University, I started my own linear motor consultancy in London and worked on a project to design systems for US Navy aircraft carriers. In 2006 I decided to focus on more ethical projects, in particular using linear motor technology designed for mining and defence projects to convert energy from ocean waves into electricity.

How did you get involved with hyperloop?

In 2013 I was approached by Elon Musk’s Hyperloop project to help design the linear motors, the propulsion, levitation and breaking systems for Virgin Hyperloop One.

Hyperloop technology aims to transport people from city to city in sealed tubes at high speed using linear motors and magnetic levitation.

How did Magway evolve?

How did Magway evolve?

I first met Magway’s co-founder and Chief Commercial Director, Phil Davies seven years ago at an entrepreneur’s programme run by the Saïd Business School and Goldman Sachs.

We are both fans of hyperloop and started thinking about how we could take this technology and adapt it to make it easier to get off the ground – the key was to remove humans from the equation and to scale down the size of the system.

We decided to focus our attention on reducing the carbon footprint of e-commerce and find a different way to move goods from automated warehouses like Amazon and Ocado to distribution centres. We first sat down with Ocado in 2017 – the year we started the company – so from the very start we were working with real world customers meeting real world needs.

How does Magway work?

How does Magway work?

Magway is a revolutionary way of transporting goods, parcels, and groceries in pods through a network of underground pipes similar to the ones already used by electricity, gas and water companies. The network doesn’t rely on batteries it is powered by a magnetic motor.

Magway has the scale to accommodate all of the UK’s online grocery deliveries and 90% of online orders from companies like Amazon. A single pipe will be able to run 12 million journeys per week, this is equivalent to the capacity of the state-of-the-art distribution facility. Magway is the only e-commerce solution we are aware of that addresses carbon emissions, congestion and supply chain resilience.

Where will the tracks run?

The network is made up of 3,500 km of track but that connects over 50% of the entire UK population to a Magway system. We have focused on the top 1% densely populated areas in the UK.

Which part of the network will you start working on first?

To start with we want to bring consolidation centres and distribution centres closer together with Magway tracks. Primarily we are focussing on two routes– Milton Keynes in Buckinghamshire to Park Royal in West London and Hatfield in Hertfordshire (where Ocado’s headquarters are) to Park Royal.

The majority of logistics companies in the UK own consolidation centres near Milton Keynes and Park Royal is a huge industrial estate which houses distribution centres for over 400 logistics companies including Ocado, DPD and UPS.

What are the environmental benefits for logistics companies using Magway?

While logistics companies have benefited tremendously from explosive online growth they know their business model isn’t sustainable because they cannot grow their businesses by putting normal vehicles on the road. We have done lots of work with stakeholders including Yodel, UPS and Doddle and while we are indirect competitors they have been incredibly positive about Magway as we are providing the solution they need to continue to operate in cities.

But many logistics companies are already using electric vehicles for last mile delivery?

The concept of the last mile is a misnomer because the last mile is basically 50 miles from consolidation centres to front doors. We intend to shorten that 50 to within 5 miles. This will enable companies to use their last mile solutions more efficiently – be it electric bicycles, electric delivery vehicles, drones or traditional vehicles.

How could Magway help the UK achieve zero emissions by 2050?

We have recently completed an Innovate UK project with Ocado, Old Oak and Park Royal Development Corporation, Space Syntax, Force Engineering and TRL. The final report by TRL concluded that by 2050, when the electricity supply network will be substantially decarbonised, Magway will achieve a reduction of 98% in emissions compared to Heavy Goods Vehicles. At scale, Magway could achieve a saving of 6 million tonnes of CO2 emissions in the UK.

How will it work in practice?

Magway will rent the track, the technology and the software to an operator like a toll road or a railway.

For our customers for example Ocado/ Tesco/Amazon or a retailer like River Island they wouldn’t be paying for the infrastructure they will be paying for the journey to get goods from point A to point B.

The operating costs are so low we are able to offer customers 50% savings on their current transport. We anticipate longer routes will be financed by infrastructure firms possibly together with private partnerships and government involvement.

Why are the operating costs so low?

It is quite simple we remove the cost of the driver, we remove the engine from the vehicle and we also remove the energy source. So even with a fully articulated lorry, 50% of the weight of the total vehicle is the vehicle weight. We have reduced our vehicle weight down to 20% of the total vehicle weight so the electrical energy we put into the system is used very effectively. Also we don’t have any moving parts within the vehicle so maintenance costs are very low.

What has been the reaction to Magway?

Right from the start people have really connected with the concept of Magway. We have had amazing engagement from across central and local government, suppliers, customers and partners. Funding wise we have won two Innovate UK grants, were selected as one of the top 100 Global Startups in 2019 and before lockdown Magway had just closed a funding round, raising £1.5 million from 2,000 investors.

How could Magway help in a future pandemic?

When you get a shock event like the coronavirus pandemic you need the supply chain to remain resilient. Particularly critical supply chains to hospitals, other frontline services and even food.

Magway would be able to deliver goods regardless of a sudden, unplanned increase in capacity.

Also in a post COVID world people are looking for more contactless options for delivery.

Amazon, Ocado and many others operate highly automated warehouses but when the goods leave the warehouse it becomes a very manual process. With COVID all those manual interventions pose the risk of contagion.

At Magway we can automate the whole process and when the goods arrive at the consolidation centre we could pass them straight onto an autonomous drone/ click and collect facility.

So Magway could give logistics companies, retailers and customers more certainty?

We remove the uncertainty from the truck journey. There are no delays caused by traffic, weather and sick days. From the customer perspective the whole network is automated so we know exactly where the goods are at all times so we can help companies provide a better customer service.

How do you ensure the system is secure?

As we design the system we create digital twins which enable us to assess security risks and address them before the system is built.

We will scan everything that goes into the pipes but also the vehicles have got multiple sensors on them which includes live video feeds, thermal vibrations and temperature sensors so If anything is happening to our vehicles or there is a security breach in the tunnel we can sense it from the electric current.

In terms of people stealing from the system – the vehicles are travelling at 60mph through an enclosed pipe and the vehicles are completely sealed so people wouldn’t know if they are getting eggs or an iPhone!

What are the biggest obstacles to getting the technology up and running?

Initially we thought the biggest obstacle to Magway would be regulatory but when we started looking in detail we found a number of mechanisms for us to get planning permission. The surprising thing is in 1992 the Department of Transport had already made provisions for linear motor systems like Magway. So in terms of the biggest obstacle to Magway – we have identified a very attractive market and have a lot of engagement, but the biggest challenge is finding that first pilot and being able to show customers Magway operating.

Which brings us onto your new facility – what will people be able to see there?

This month we are moving into a facility four times the size of our current one. We will be able to bring people in and show them an operational pilot – they will be able to see the Magway system moving at speed, demonstrate going into a tunnel, going into a warehouse, unloading and reloading pallets. This operational pilot brings us closer to a commercial pilot which we hope to achieve over the next 12 months.

What is your key motivation?

We are really driven by sustainability and reducing congestion. In the early days of Magway I attended a conference on the future of transport in Cologne, Germany and an academic from the University of Leeds presented her a study on what future cities should look like. Part of her project involved giving a group of children a blank sheet of paper and asking them to draw the city of the future. You’d expect to see flying cars or drones. But what did the kids draw? They drew paths, people riding bikes and walking and playing football! Since lockdown began I have been cycling round London with my 12 year-old daughter and 14 year-old son– and what an incredibly beautiful city it is without any cars – this is what cities should be like.

Phill Davies, Co-Founder & Chief Commercial Director at Magway will be speaking at our virtual event Post&Parcel Live which will be held on 17-18 June 2020. Register for free today.