Last mile: robotic revolution

Many companies have long been trying to address problems of congestion and safety created by e-commerce in already overcrowded cities.

Post & Parcel speaks to Lukasz Nowinski, CEO of Retail Robotics and Julian Kozankiewicz, Chief Product Officer and Partner at Retail Robotics to find out about a revolution in the parcel lockers market, which is not only key to last mile delivery in cities but also provides the ultimate contactless delivery experience which people have been increasingly longing for. Their innovative machines are already being deployed with their first major business partners.

How has COVID-19 changed the delivery outlook for overcrowded cities?

Lukasz: Our machines haven’t been designed with a pandemic in mind, but to address challenges faced by retailers, consumers and cities. Click & Collect solutions are actually the ultimate last mile delivery option, especially for people living in congested areas. Sure, due to COVID-19 lockdowns, almost all industries reported a high increase of online ordering. There were cases, like in e-grocery, where customers had to wait weeks before their goods were delivered. This happened because the supply chain, specifically the last mile, is very complex and not very efficient. Our goal is to revolutionize the last mile in congested city centres, and the pandemic has actually almost nothing to do with this.

How has online shopping changed recently?

Lukasz: Online shopping ratios have been growing year on year, which affects growth in urban last-mile deliveries. To get an idea of the situation, in 2019, in New York alone, 1.5 million packages were delivered every day. Now, reports from all over the world indicate that the surge in online sales is faster than ever and we are unlikely to return to where we were before. Consumers expect to have fresh groceries and pick-up options available close to their home or office. But it is extremely difficult to redesign shops in dense city centres to give them such new capabilities.

Can you tell me a bit about your background and why you set up Retail Robotics?

Lukasz: My father started a mechanical engineering company, Aqmet, over 30 years ago. I inherited his innovation, responsibility, passion and eventually the whole company from him. Back in 2008 I co-created and co-managed the development of the biggest traditional parcel locker network in Europe – Inpost. We decided to do a large scale roll which turned out to be and remains very successful – 10 000 units produced in our factory were installed in Poland, UK and Italy. At the same time as my work for Inpost, over the years I have been monitoring the market, looking for disruptive last mile services, providing e-commerce and retail with thoughtful solutions and set up Retail Robotics to explore this. Over 4 years we have developed two new solutions, PickupHero and Arctan, which are in the pilot phase and will soon be implemented on a massive scale by our business partners in France, Poland and the UK.

Julian can you tell me about the design of the lockers?

Well, first of all, the machines we have designed are by far different, and superior to the lockers you already know. In the first phase of development we visited and scouted hundreds of convenience stores in Asia, Europe, and the United States in search of the right way to fit a parcel locker across an entire store chain. It took us several years to overcome all the technical challenges we came across.

Eventually, we were able to fit about a hundred parcels within less than 1m2 of retail space, something that had never been seen before. That is only possible thanks to the robotics technologies we developed ourselves. Obviously, the patent is already pending.

Can you tell me about your existing deployments??

Julian: In June 2020 we launched the first of our click & collect robotic machines – PickupHero – an automated parcel collection point, which doesn’t require a shop assistant to be involved. Owing to the use of a robot instead of a traditional locker system it occupies a small portion of the retail space, which is at a premium in smaller stores. A major part of the installation can be located behind the shelves. Due to its capacity and smallest footprint, this solution is unparalleled in the parcel locker market, which are traditionally only suitable for bigger spaces. According to our estimates it can fit 90% of local stores. For retailers it means increased in-store footfall with up to 70% pick-up to purchase ratio. The solution can reduce last mile delivery costs, but also traffic and pollution by up to 90%. First device was installed at Zabka convenience store chain in May 2020.

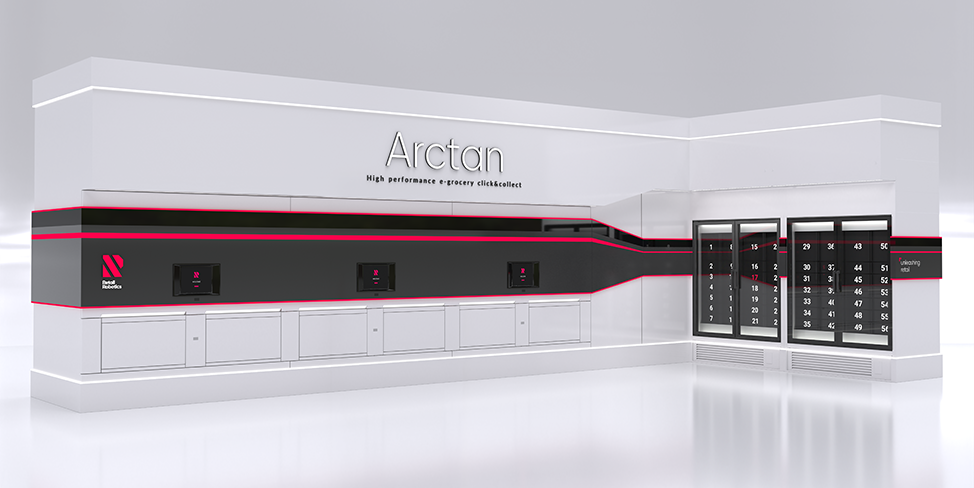

Lukasz: Arctan was designed to revolutionise shopping. The system consists of a single block of storage for logistic bins (94 or 202 depending on the version chosen). And the delivery device itself is made up of hatches that open to give customers access to their command, without human intervention.

The customer scans a QR code in front of a reader, which triggers the delivery of the order. The corresponding bins (with the orders) are brought by an automatic device from the storage area to the collect & load drawer. The customer collects his groceries, then the drawer closes. If the order contains frozen foods, these must be collected in a specific cabinet. Two or three customers can collect their order simultaneously (depending on the module installed). Arctan is dual-temperature (4 degrees and -18° for frozen foods, which are stored in a dedicated freezer) and emphasises compactness of installation.

In September 2020 we installed the first Arctan in Paris. The first consumers’ comments are very positive – they appreciate convenience, simplicity and possibility of orders’s collection whenever they want. We strongly believe that our solution, developed in next months, will provide clients with the best user experience, helping retailers to increase customer loyalty in a very competitive online environment.

How has the uptake of click & collect changed recently?

Julian: It is not surprising that e-commerce and retailers are considering click & collect machines to improve the delivery process, indeed usage rates have started to grow in recent years (almost 30% growth in 2019). People are opting for click & collect not only for parcels but also groceries and since the 2020 it has been even more popular as people are looking for ways to avoid going into stores and shopping face to face. The number of households that have used online grocery services in the U.S. in March 2020 doubled compared to August 2019 (approximately 40 million Americans). This new way of shopping is also becoming popular in the UK, France and other European countries. Thanks to click & collect machines like Arctan, picking up food purchases ordered online is fast and safe. Arctan can be located inside or directly outside of the shops as an addition, or as a standalone implementation in dedicated premises, which makes purchases possible to be collected 7 days a week and 24 hours a day. Arctan machines are equipped with a refrigerator and freezer module, so consumers can be sure of the freshness of purchased products – even if they pick them up later than planned for.

How can your solution help with congested cities?

Julian: In the Arctan machine network, one courier with a car can deliver from 200 to 300 e-grocery orders a day, covering 30-40 km (18-24 miles). Meanwhile, traditional home delivery takes one courier to deliver 14-30 orders, covering 160 km (100 miles). This means huge optimisation, but it will not only affect the drop-in costs of delivery. It will reduce traffic in cities, where courier cars occupy pavements and streets, making it difficult for drivers and residents to move around the city. Eventually, it can reduce CO2 emissions by up to 40 times or more, which makes a great difference on a global scale.

How can such a network help retailers fulfil orders?

Lukasz: In France and other countries in Western Europe, a courier is able to fulfil approximately 14 to 30 e-grocery deliveries for customers a day. Our business partners told us that when COVID-19 first hit the e-grocery stores had the potential to increase even a few hundred percent, but they could only double, because of the saturation in the current operational model. Online stores had to close the slots for customers and even then – the delivery of an order took 10 days or more. Click & collect machines are more than a good solution for all sides – customers, stores and courier companies.

Are click & collect solutions a longer-term solution?

Lukasz: In the long term they are conducive to the ecology and comfort of city dwellers. They will reduce the cost of the last mile by approximately 80% or more. Bearing in mind that according to this year’s World Economic Forum report, by 2030, 60% of people will be living in cities, we should draw conclusions from how e-commerce surge affects cities and look for ways to address the challenges of congested cities. With click & collect machines we begin tackling the issues right away.

Biographies

Łukasz Nowiński

Łukasz Nowiński

Founder and CEO of Retail Robotics. Interested in new technologies and their impact on logistics. Skilled in e-commerce, Retail, Robotics, International Environment and Automation. Co-created and co-managed the biggest traditional parcel locker network in Europe – Inpost. To date, Retail Robotics has produced more than 10,000 parcel locker units for Inpost while continuing to build its own solutions.

Julian Kozankiewicz

Chief Product Officer of Retail Robotics. Expert in automation, robotics and IoT. Interested in retail with focus on last mile robotic solutions and omnichannel consumer experience. Founder of Noa Tech company, which has been designing and implementing self-service and automated solutions since 2013. Co-creator and supporter of TEDxWarsaw.