Warehouse Teams and Robots: Collaborating to Meet Rising Demands

The role of automation in warehouse logistics has evolved beyond just cutting costs and boosting output. Nowadays, due to labour shortages, many are turning to robots and advanced vision systems to handle increasing orders without overburdening their staff. This shift is proving that rather than replacing jobs, automation plays a vital role in enhancing working conditions, boosting employee morale, and addressing staff shortages.

Dirk van Lammeren, CCO of Prime Vision, sheds light on how automation is becoming a go-to strategy for retaining and attracting staff in the warehouse industry.

Tackling Staff Shortages and Retention Challenges

Tackling Staff Shortages and Retention Challenges

“The logistics sector has long grappled with staff shortages. A study showed a drop in job applicants per position from 6-10 in 2013 to just 2-5 by 2018. The pandemic only worsened these conditions, with many workers retiring or exiting the industry. Additionally, the aging workforce and the younger generation’s disinterest in warehouse jobs have compounded the problem.

In the U.S., an MHI and Deloitte report highlighted that 57% of respondents identified hiring and retaining skilled workers as their primary supply chain challenge. Similarly, a UK survey by the CILT found that 86% of companies experienced staff shortages in the past two years.

Another significant issue is staff retention. Traditional warehouse roles, often physically demanding and monotonous, have led to high turnover rates. Recruiting and training new staff, especially during labor shortages, is costly and challenging.

In this era of booming e-commerce and high order volumes, attracting and maintaining a strong workforce is critical for warehouse managers to meet demand and sustain profitability. Automation is emerging as a key solution to these challenges.’’

Robots as Team Members

“Autonomous Mobile Robots (AMRs) are now integral to modern warehouse operations, efficiently transporting goods. They offer scalability and operational smoothness, surpassing traditional conveyor systems. Besides streamlining processes, robots significantly improve working conditions.

Initially, Prime Vision had to assure employees, unions, and stakeholders that robots would complement, not replace, human jobs. Now, perceptions have shifted dramatically. Robots are now seen as teammates, alleviating the physical strain on workers by handling heavy lifting and improving safety with advanced navigation and emergency stop features.

Human-robot collaboration is also enhancing the efficiency and safety of warehouse operations. Prime Vision specializes in creating environments where humans and robots work in harmony, leading to increased efficiency and job satisfaction. These positive interactions have led to a warmer reception of robots, with workers even giving them names and integrating them as part of the team.”

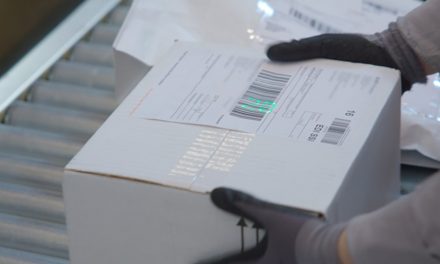

Enhancing Sorting with Computer Vision

“Computer vision is also playing a key role in addressing staff shortages and other logistics challenges. Overcoming language barriers in multinational teams is a significant hurdle, particularly in sorting tasks. Prime Vision’s Flow Projector, for example, simplifies the sorting process by projecting numbers on parcels, indicating their sorting destination, thus reducing training time and enhancing efficiency.

This technology not only increases sorting effectiveness by 30-40% but also improves working conditions by eliminating tedious manual tasks like label scanning. The Flow Projector’s popularity among workers is evident, with some even arriving early to be able to work at stations where it’s in use, reflecting job satisfaction and motivation.”

Automation Beyond Efficiency

“While automation has long been valued for improving efficiency, throughput, and profitability, its role in enhancing softer aspects like employee satisfaction, retention, and working conditions is now equally recognized.

Prime Vision’s solutions aim not to replace workers but to relocate tedious tasks to machines, allowing humans to focus on more stimulating activities. This interface between humans and machines simplifies work and boosts safety.

The choice for workers is clear: work in a traditional, manually-intensive warehouse or in a modern facility with cutting-edge technology and supportive robots.”

A New Narrative for Automation in the Workplace

“The narrative of automation in warehouses is shifting. It’s no longer just about doing more with the same workforce; it’s about making warehouse work more rewarding and appealing. Automation is creating new opportunities for technical, supervisory, and managerial roles, offering safer, more skilled, and fulfilling jobs than traditional manual labor.

This change in perspective is evident among warehouse employees. A recent global study found that 60% of workers view the adoption of new technology positively. Automation is not just about improving efficiency or handling higher volumes with fewer resources; it’s revolutionizing warehouse work, making fulfillment about more than just filling orders.”

About Dirk van Lammeren

Dirk van Lammeren, the Chief Commercial Officer at Prime Vision since 2019, brings a dynamic blend of a Master in Business Administration and two decades of experience in the postal and parcel industry. Renowned for his passion in logistics, technology, and innovation, Dirk has made significant contributions internationally. His expertise in leveraging lean Startup methodology for fast-paced and efficient corporate innovation is noteworthy. At Prime Vision, he is instrumental in steering marketing, sales, and service management. Dirk’s role in shaping the company’s product roadmaps showcases his commitment to driving growth and embracing cutting-edge solutions in the logistics sector.